The Ultimate Guide on How to Maintain a Fire Rated Door

Properly maintaining a fire rated door is vitally important to the success of protecting a building's structural integrity, occupants, and assets during a related emergency. After all, a fire rated door is only as reliable as the state it's left in. Because of the severity of its importance, we've provided an all-encompassing rundown of fire door maintenance, including what fire doors are, why maintaining them is crucial to their success, and essential steps and tips for better operation and preparation.

What are Fire Rated Doors?

Rolling Fire Doors are rolling steel doors that have been engineered, tested, and approved by authority with a fire rating. These doors are designed to withstand smoke, heat, flames, and other related elements for a specific amount of time. Typically, fire ratings are 4 hour, 3 hour, 1-1/2 hour, or 45 minutes depending on manufacturer.

Why is maintaining a Fire Rated Door Vital to its Operation?

Understanding the importance of fire rated doors and how to keep them maintained in compliance with the national Fire Protection Association (NFPA) is crucial to their operation. These doors are designed to slow and prevent the spread of fire throughout a building; when they aren't properly maintained, they will not protect your building from these elements and can result in severe damage if fire emergency occurs. In reference to NFPA 80, rolling fire doors should be tested annually to check for proper operation and full closure.

Note: This following steps information should not be used as a substitute for instructions from individual manufacturers. Always consult with individual manufacturers for specific recommendations for their products, and check the applicable local regulations.

4 Essential Maintenance Steps for Fire Rated Doors:

DOWNLOAD THE DASMA TECHNICAL DATA SHEET #271 ("Rolling Steel Fire Doors: Drop Testing and Annual Follow-Up") for more detail and information on the following procedures.

STEP 1: VISUAL INSPECTION

Perform a visual inspection, looking for anything that is out of place or could cause hazard during the drop testing or operation of your fire rated door.

Things to look for:

- Mounting and assembly bolts are not missing or loose.

- Welds and weld locations comply with installation method for fire door assemblies welded to steel jambs per manufacturer's installation instructions.

- Fusible links are located per manufacturer's instructions.

- Guide assemblies have the required fire expansion clearance per manufacturer's instructions.

- Fusible links and sash chain/cable links are not painted or coated with dust or grease, cable is not kinked or pinched, chain is flexible and not twisted, and raceways are not obstructed.

- Smoke detectors/release devices function properly.

- Nothing that is not a part of the fire door assembly is attached to any part of the fire door assembly (suspended ceiling, light fixtures, ducting, conduits, framing and any other building materials).

- There is no damaged or missing components on fire rated door.

STEP 2: OPERATIONAL CHECK

Using normal operation, open and close the fire rated door and inspect for any indications of damaged parts. If the door is not properly balanced, or there is damage or missing parts that could create a hazard or prevent the proper operation of the door, have these issues corrected before conducting a drop test.

Important: Make sure your fire rated doors remain in an operative condition, in accordance with NFPA 80, at all times.

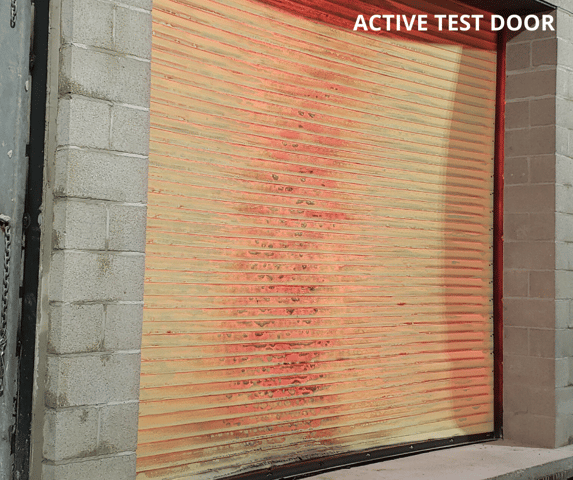

STEP 3: DROP TEST

Drop testing your fire rated door should be completed annually to ensure the assembly will close completely and accurately in an emergency. This test ensures the door will close fully with the bar resting on the sill, with an average closing speed of at least 6" per second, while not exceeding 24" per second. While we've established steps as a general outline, they are not a substitute for an individual manufacturer's instruction, so make sure to reference manufacturer's instructions when applicable.

Things to Remember:

- Have a trained technician perform an inspection and drop test of all fire door automatic closing features.

- Correct any issues that resulted during the visual and operational inspection before performing drop test.

- Components may fail during the drop test that are not the fault of the service provider and are not included in the cost of the drop test.

- Document the drop test with the DASMA Drop Test Form.

- Drop test the door twice to verify proper operation, full closure, and that automatic closing devices were properly reset.

STEP 4: DOOR RESET

Reset the fire rated door per individual manufacturer's instructions. Open and close the door by normal operation and drop test the door a second time, and reset again to ensure your door is ready for operation.

Tips & Tools for Better Operation and Preparation:

In addition to proper maintenance, there are several "best practices" to remember when utilizing fire rated doors. Download our info-graphic for more information on each of these tips. All it takes is one person to not follow the best practices in your building for a fire rated door to not perform properly during an emergency. To get your shareable version of this infographic, download a copy below.