How to Easily Keep Your Fire Door up to Code

Fire Doors are instrumental tools for fire rated applications, but their reliability can be jeopardized easily by simple mistakes such as mounting a sign, painting a component, or not staying up to date on routine maintenance. That's why we've outlined 3 tips regarding common mistakes to avoid, as well as the best maintenance tips and tricks in the book. After all, the best way to stay prepared for an emergency while sustaining your rolling door's fire rating is through education, as well as learning what not to do.

What You Need to Know to Not Accidentally Void Your Fire Door Rating

First and foremost, it's vital to your protection to keep up with codes and standards for your fire rated doors, and make sure they're in compliance with the National Fire Protection Association (NFPA). Keeping them maintained leaves them in a continuous and reliable state of readiness to close and secure a fire rated application when activated.

3 things you should never do to your fire door

It's safe to assume that anything not apart of a fire door assembly should not be attached to any part of that assembly, as field modifications are the number one reason for voided fire ratings.

- Don't paint

- Don't drill or screw any holes into your fire door or assembly

- Don't put off repair

Don't Paint

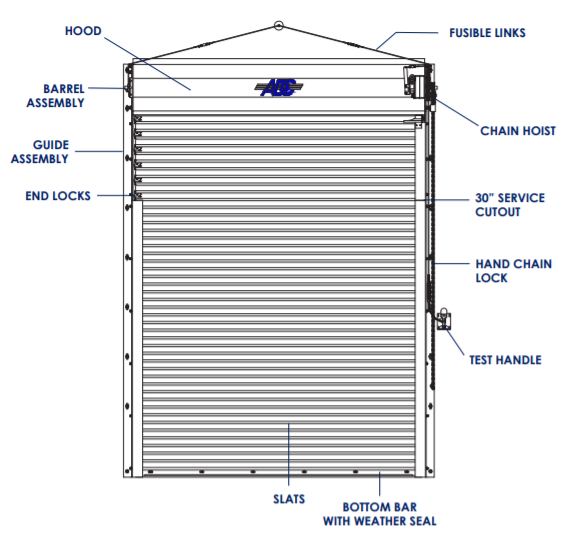

While you may be wanting your fire door to blend in seamlessly to your application, don't paint components on your fire rated door. Painting components could alter your door's functionality and void your fire door rating. Fusible links for example were developed to perform a safe emergency closing. When activated, the door automatically descends to the floor at a controlled rate, eliminating the danger of a free falling door. When these links are painted, the automatic closure of your door could be effected. If your door doesn't close properly, there is no protection from a spreading fire throughout your building.

Not only can paint effect the functionality of a door, but it's also common for people to accidentally paint over the fire door's label. This mistake effects more than the aesthetics of your fire door, without a fire rated label, your door is not certified.

While you shouldn't paint components, there are other ways you can achieve your design needs. Industry leading rolling steel doors can be powder coated, which is a durable baked-on layer that adds protection to your door's curtain. This durable coating can come in virtually any color to meet your design needs, and has the advantage of lasting much longer than traditional paint.

Don't Drill or Screw Any Holes into Your Fire Door or Assembly

Creating a hole anywhere in the fire door assembly is bad news. Fire feeds on oxygen, so it's important when trying to slow or prevent the spread of fire that you're not fueling it's oxygen supply. Not only would this hole create a passageway for oxygen and jeopardize your protection, but it would void your fire rating as well.

Don't Put Off Repairs

If your rolling steel fire door is subject to damage, whether that's a bent slat or damaged bottom bar, make sure to repair it immediately so that your door remains in a continuous state of readiness. When repairing or replacing components that have broken or failed inspection, remember to replace these components with parts from the original manufacturer of the fire door, as they have to be maintained in the state they were originally tested.

Repairing your rolling steel fire door can be made easy with extended service cut-outs. With 30" service cut-outs, you can install and maintain your fire rated door easier than ever before.

How do you maintain a fire door? A variety of steps should be routinely completed; such as, visual inspections, operational checks, drop testing, and resetting your door.

- Visual Inspections: look for anything that is out of place or could cause hazard during the drop testing or operation of your fire door.

- Operational Checks: Using normal operation, opening and closing the fire rated door and inspecting for any indications of damaged parts.

- Drop Testing: Should be completed annually to ensure the assembly will close completely and accurately in an emergency.

- Reset: This should be done per manufacturer's instruction, and completed two times to ensure your door is ready for operation. The 500 Series rolling steel fire door has an automatic reset that ensures an easy, fast and safe fire door drop test for both chain hoist and electric motor operations.

By following our tips on what not to do and pairing them with routine inspection, operational checks, and drop testing/resetting, you will have a reliable fire door to protect your building at all times.

Have Questions? Read our blog, "The Ultimate Guide on How to Maintain a Fire Rated Door" for more information and tips on what to look for during a visual inspections, how to prepare for operational checks and more regarding routine maintenance.